Third ERASMUS+ SMARTRAIN project mobility (Spain)

During the first week of May, the European Erasmus+ SMARTRAIN project held the third of its mobilities, where Spain was the hosting country. It counted with the presence of students and teachers from Belgium, Italy and Spain.

With the coordination of AIDIMME and the CIPFP CATARROJA – Spanish partners of the project – a schedule of training activities was prepared in both centres and visits to companies of interest for the students and teachers who participated in the mobility, such as EMUCA, VICCARBE, KOO INTERNACIONAL and GRUPO ROYO. We would like to thank all of them for their predisposition and excellent attention.

This third mobility is focused on smart furniture and the possibilities it offers when it is incorporated into the furnishings, and to show the progress made in each of the collaborative projects that are being carried out in each country.

The three projects are clearly distinguishable, which allows us to see the different possibilities of incorporating the knowledge acquired in the development of the project by the participating students and teachers.

THE PROJECTS

Within the framework of a collaborative methodology («Project Based Learning») and learning through the direct handling of the concepts learned in the workshops («Learning by doing»), each of the groups alternated working in mixed teams with members from all the countries and working in their own country groups. Throughout this, they have incorporated the concepts of CIRCULAR ECONOMY, ADDITIVE MANUFACTURING and SMART FURNITURE into each of their projects, so that in the end the participating students and teachers achieve an enriching result that can be easily extrapolated as a working methodology.

SPANISH PROJECT. KPORT

It is a base that can be used with laptops and tablets, which incorporates recycled materials, and a series of sensors and ports.

ITALIAN PROJECT. ILLUSION LAMP

In this case, the project is basically a lamp made from recycled wood inspired by the Moebius strip. The wooden packaging material has also been designed using laser cutting.

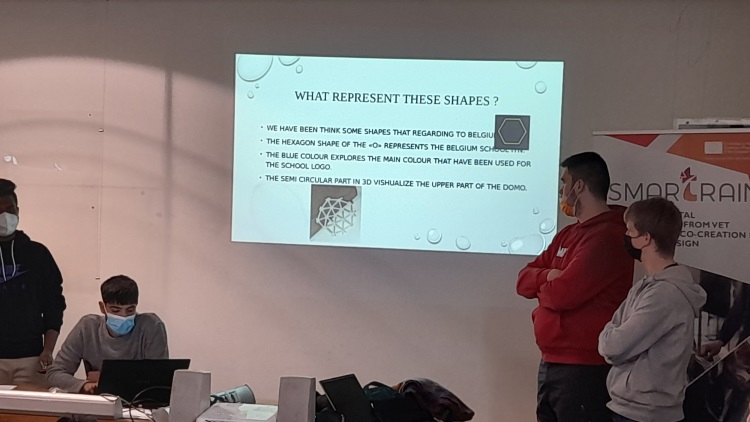

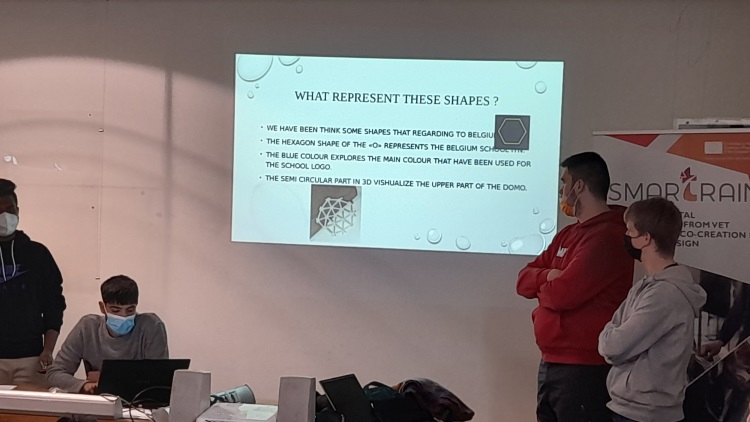

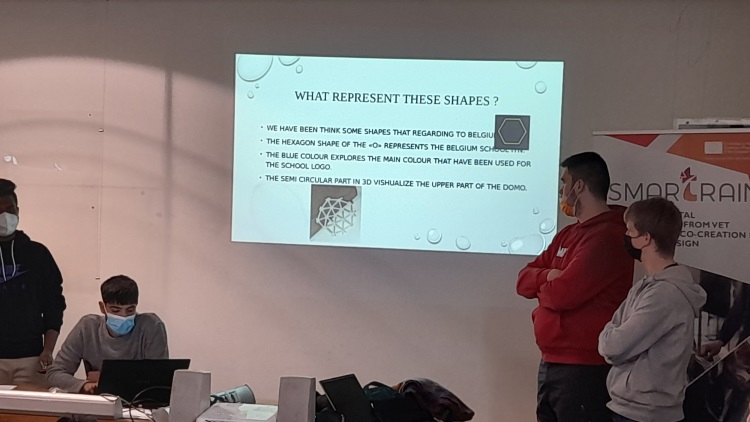

BELGIAN PROJECT. MUSIC DOME

The MUSIC DOME project – completely different from the rest – creates a work or leisure space, in which the modularity of the construction elements and the possibility of incorporating lights, sensors, loudspeakers, etc. stand out.

TRAINING AND GROUP WORK

Throughout the 3rd, 4th and 5th of May, the students received practical training at AIDIMME and at the CIPFP CATARROJA on the electronic components that can be found in smart furniture, with special emphasis on those that were of greatest interest for the projects of the three groups. The training covered the need to know the basic aspects of a connection between sensors and a mobile app, a key factor in all the projects.

In both locations, students and teachers from Italy and Belgium visited some of the facilities at AIDIMME and the CIPFP CATARROJA.

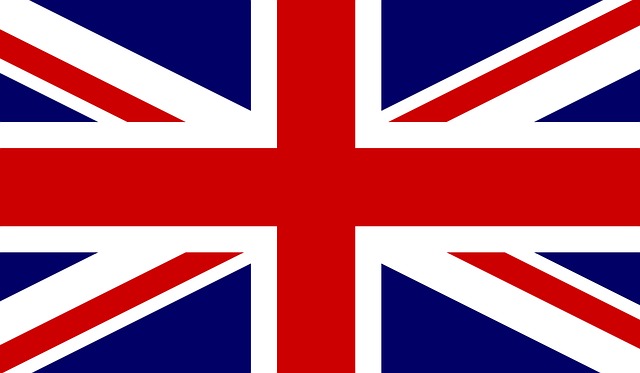

They visited AIDIMME’s Additive Manufacturing and PLASMA project facilities, and were offered explanations from AIDIMME technicians Mario Martínez and Antonio José Martín, from the Technologies and Processes Department.

The training at AIDIMME was conducted by technicians from the TECHNOLOGIES AND PROCESSES Department: Juan del Agua, ICT & Industrial Development technician, and Fernando Gigante, from Information Technologies.

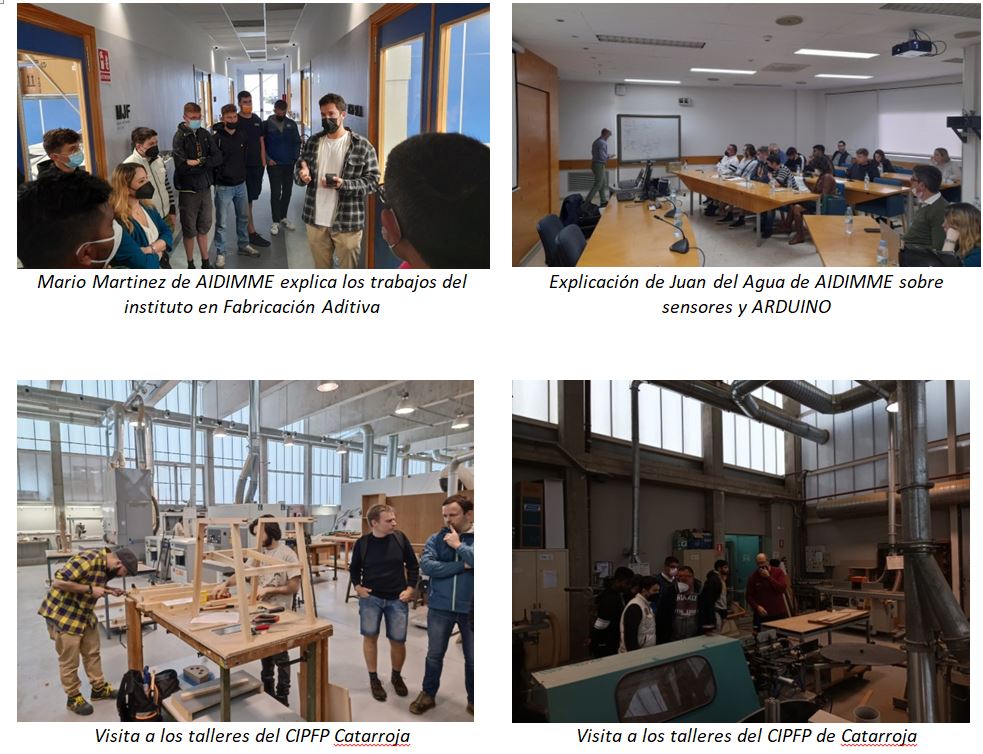

At the CIPFP Catarroja on the 4th and 5th of May, students and teachers were able to handle and learn first-hand about sensors, ARDUINO boards and how to program the set of elements. Lorena Silvent Ruiz, Deputy Mayoress at Catarroja Town Council, visited the event and welcomed the participants of the mobility in Spain.

Under the coordination of Francisco Aparici, teacher of the CIPFP of Catarroja, the students studied and tested in a practical way the use of all the necessary elements for the instruction of sensors, basic programming, etc., in order to finally incorporate these elements into their projects.

On the last day of the mobility, the groups from each country made a presentation of their projects, which was led by Cecilia Amo, Project Coordinator at CIPFP Catarroja, with the participation of students and teachers from CIPFP Catarroja.

It also counted with the remote collaboration of Dr. Oliver Jancke, Business Development Manager at INNOVAWOOD, who asked questions about each of the projects presented: the recyclability of the components, possibilities of selling them on the market, etc..

THE VISITS

For the mobility, a visit to four companies in the sector was prepared, so that students and teachers could see first-hand the ways to apply the concepts learned, the companies’ point of view who are very focused on these mentioned concepts market-wise, the importance of design, the difficulties of production, etc.

VISIT TO VICCARBE

Rubén Mateos, Product Manager at VICCARBE Habitat, S.L., guided the members of the SMARTRAIN project to learn about the company’s concept of smart furniture, who visited the facilities in Beniparell.

Viccarbe is an international benchmark in the manufacture of collaborative furniture and, since its inception in the year 2000, its goal is to bring Mediterranean experiences to unique work, leisure and home environments around the world, through the creation of multipurpose chairs, stools, armchairs, sofas, tables and accessories.

The firm, founded by Víctor Carrasco, was granted the Prince of Asturias Award for Business Excellence in Design and is present in more than 80 countries, where it participates in the development of collaborative furniture for companies such as Apple, Google or LinkedIn among others, helping to foster collaboration, creativity and productivity in their workspaces.

VISIT TO KOO INTERNACIONAL

On behalf of KOO International, the group was attended by Jose Muñoz, Factory Manager, Jorge Mompó, Technical Manager, and Diana Castellano, Marketing and Innovation Manager.

Diana made an interesting presentation about the company, and especially about a concept that the company – with the collaboration of the GPS Section of AIDIMME – is committed to: circular economy. José Muñoz and Jorge Mompó exchanged impressions with SMARTRAIN students and teachers about the key characteristics of their products, such as their resistance, the possibilities for updating and repairing products, the types of filler material, etc.

KOO International is a seating furniture manufacturer with more than twenty years of experience in the industry, creating pieces based on design, innovation and consistency. It has won numerous awards in product design and has collaborated with renowned designers.

Under the name of CIRKOOLAR, the SMARTRAIN participants were able to learn how the company carries out its approach to the concept of circularity: https://www.koointernational.com/landings/cirkoolar/

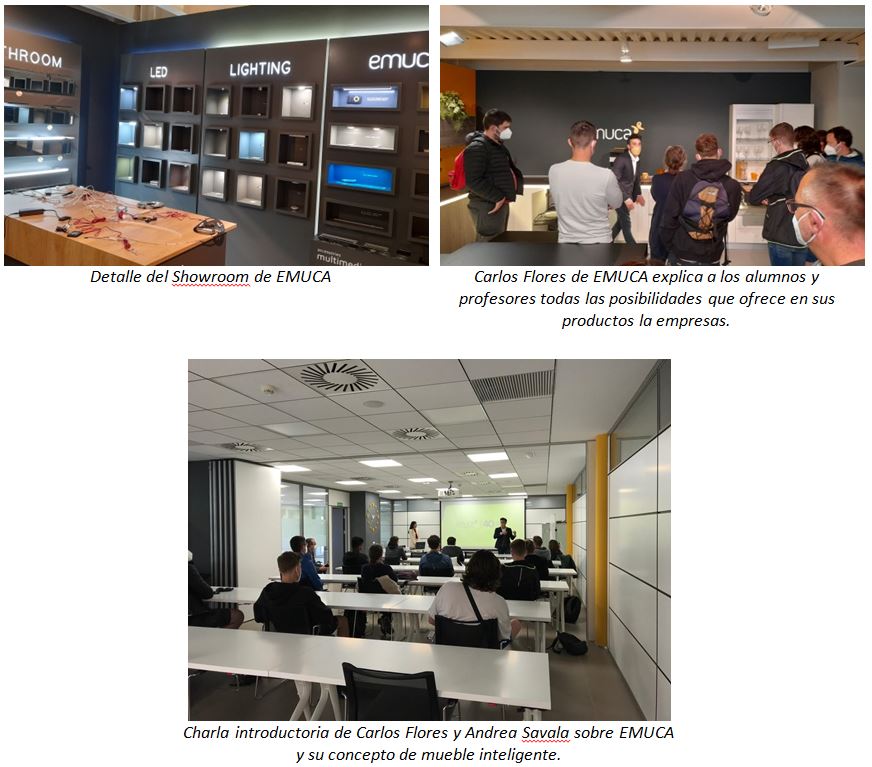

VISIT TO EMUCA

The visit to this company was conducted by the Corporate Manager Carlos Flores and Andrea Savala from the Marketing Department.

EMUCA GROUP designs, manufactures and markets a wide range of products for the furniture, carpentry, hardware and DIY sectors. The company has commercial offices in Spain, Italy, United Kingdom, France and Portugal, which allows them to be in direct contact with the latest trends in the furniture sector and the Innovation department to transfer them to their products.

The students learned about EMUCA’s perception of the smart furniture concept, in which the user’s needs play a key role, without losing sight of concepts such as sustainability and circular economy.

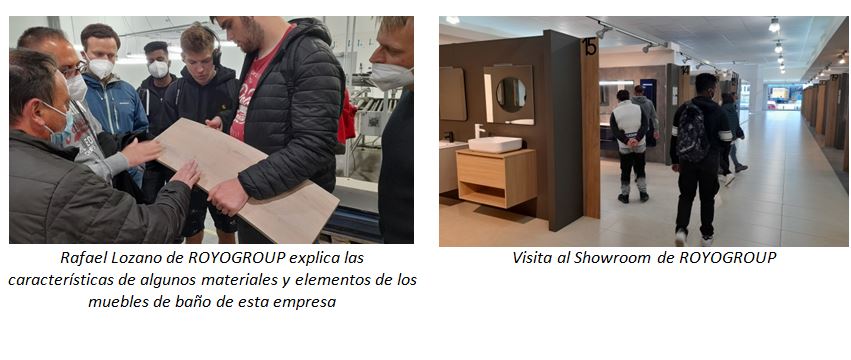

VISIT TO MOBILIARIO ROYO

The last visit was made to the most important bathroom furniture company in Europe, ROYOGROUP. Its position has been strengthened since 2021 when it allied with the ROCA group, becoming responsible for manufacturing the firm’s bathroom furniture.

It is a company committed to sustainability, the modernisation of production processes and is also very active in the field of R &D, participating in numerous research projects.

On this occasion, the person in charge of the visit on behalf of ROYOGROUP was Rafael Lozano, the company’s Process Specialist.

During the visit, students and teachers were able to see first-hand the production process of the company, the characteristics of certain materials used and the wide variety of manufactured bathroom furniture products. It is a large industrial company, so the students and teachers found the experience very interesting.

The SMARTRAIN project is entering its final stretch and the results of the projects carried out by the three groups from Spain, Italy and Belgium will be presented shortly.

SMARTRAIN. BRIDGING PIVOTAL COMPETENCIES FROM VET CURRICULA TO CO-CREATION IN FURNITURE DESIGN

Project Number: 22000050

Grant Agreement: 2020-1-ES01-KA202-082778

Duration: From 01/10/2020 to 30/09/2022

Coordinated at AIDIMME by: SORIANO CARDO, CARLOS

R&D Line: INDUSTRIA 4.0

For more information, contact AIDIMME

Visitors: [wpstatistics stat=pagevisits time=total id=30396]

Tercera movilidad del proyecto ERASMUS+ SMARTRAIN (España)

- El proyecto europeo Erasmus+ SMARTRAIN, celebró durante la primera semana de mayo, la tercera de sus movilidades, en este caso en España, con presencia de alumnos y profesores de Bélgica, Italia y España.

- En esta tercera movilidad, con la coordinación de AIDIMME y el CIP FP CATARROJA socios españoles del proyecto, se llevaron a cabo una serie de actividades formativas en ambos centros y visitas a empresas.

- EMUCA, VICCARBE, KOO INTERNACIONAL y GRUPO ROYO fueron las empresas visitadas y despertaron gran interés en el alumnado y profesorado. AIDIMME les agradece la predisposición y la excelente atención dispensada en estas visitas.

Esta tercera movilidad está centrada en el mobiliario inteligente y las posibilidades que ofrece en su incorporación a los muebles, y por otro lado el mostrar los avances obtenidos en cada uno de los proyectos colaborativos que se están realizando en cada país.

Se trata de tres proyectos claramente diferenciados, lo que permite constatar las diferentes posibilidades de incorporar los conocimientos adquiridos en el desarrollo del proyecto, por parte de los alumnos y profesores participantes.

LOS PROYECTOS

En el marco de una metodología colaborativa (“Project Based Learning” y aprendiendo mediante el manejo directo en talleres de conceptos aprendidos (“Learning by doing), cada uno de los grupos han ido alternando trabajos en equipos mixtos de todos los países y trabajos en sus propios grupos, durante el cual han ido incorporando los conceptos de ECONOMIA CIRCULAR, FABRICACIÓN ADITIVA y MOBILIARIO INTELIGENTE, a cada uno de sus proyectos, de forma que al final se espera un resultado que sea enriquecedor para los alumnos y profesores participantes y que sea extrapolable con facilidad como una metodología de trabajo.

PROYECTO ESPAÑOL. KPORT

Se trata de una base que se puede emplear con portátiles y tabletas, que incorpora materiales reciclados, y una serie de sensores y puertos.

PROYECTO ITALIANO. ILLUSION LAMP

En este caso el proyecto consiste básicamente en una lámpara realizada en madera reciclada que se inspira en la cinta de Moebius. Se ha diseñado también material de embalaje madera realizado con corte láser.

PROYECTO BELGA. DOME

Completamente diferente al resto, el proyecto DOME genera un espacio de trabajo o lúdico, en el que destaca la modularidad de los elementos constructivos y la posibilidad de incorporación de luces, sensores, altavoces, etc…

FORMACIÓN Y TRABAJO EN GRUPO

A lo largo de los días 3, 4 y 5 de mayo los alumnos recibieron en AIDIMME y en el CIP FP CATARROJA formación práctica sobre aquellos componentes electrónicos que pueden encontrarse en los muebles inteligentes y con mayor incidencia en aquellos que resultaban de mayor interés para los proyectos de los tres grupos.

Para todos los proyectos se detectó la necesidad de conocer los fundamentos de una conexión entre sensores y una app de móviles, y la formación cubrió también esta necesidad, en sus aspectos mas básicos.

En ambas ubicaciones, los alumnos y profesores de Italia y Bélgica realizaron visita a alguna de las instalaciones de AIDIMME y del CIPFP CATARROJA.

En AIDIMME se visitaron las instalaciones de Fabricación aditiva y las del proyecto PLASMA, con explicación de los técnicos de AIDIMME Mario Martínez y Antonio José Martín, del Departamento de Tecnologías y Procesos.

La formación en AIDIMME corrió a cargo de técnicos del Departamento de TECNOLOGÍAS Y PROCESOS: Juan del Agua técnico de TIC & Desarrollo Industrial y Fernando Gigante, de Tecnologías de la Información

En el CIP FP Catarroja, los días 4 y 5 de mayo los estudiantes y profesores pudieron manejar y conocer de primera mano los sensores, placas ARDUINO y la forma de programar el conjunto de elementos.

Se contó con la visita de la Lorena Silvent Ruiz. Vicealcaldesa del Ayuntamiento de Catarroja, que dio la bienvenida a los participantes de la movilidad en España.

Con la coordinación de Francisco Aparici, profesor del CIPFP de Catarroja, los alumnos estudiaron y probaron de una forma práctica el empleo de todos los elementos necesarios para instrucción de sensores, programación básica, etc… con el fin de incorporar finalmente estos elementos en sus proyectos.

El último día de la movilidad, los grupos de cada país realizaron una presentación de sus proyectos que contó con la participación de alumnos del CIPFP Catarroja, profesores del centro, y la colaboración en remoto del Dr. Oliver Jancke, Business Development Manager de INNOVAWOOD, que preguntó aspectos acerca de cada uno de los proyectos presentados, desde la reciclabilidad de los componentes, posibilidades de venta en mercado, etc…

LAS VISITAS A EMPRESAS

Para la movilidad en España, se preparó una agenda de visitas a 4 empresas del sector, de forma que los alumnos y profesores pudieran ver de primera mano formas de aplicar los conceptos aprendidos, el punto de vista de las empresas, muy enfocado al mercado sobre estos mismos conceptos, la importancia del diseño, las dificultades de producción, etc…

VISITA A VICCARBE

De la mano de Rubén Mateos, Product Manager en VICCARBE Habitat, S.L. los integrantes de la movilidad en España del proyecto SMARTRAIN pudieron conocer el concepto de mueble inteligente para la empresa, y visitaron las instalaciones en Beniparell.

Viccarbe es un referente internacional en la fabricación de mobiliario colaborativo y desde su origen en el 2000, su meta es trasladar experiencias mediterráneas a entornos singulares de trabajo, ocio y hogares de todo el mundo, gracias a la creación de polivalentes sillas, taburetes, butacas, sofás, mesas y accesorios.

La firma fundada por Víctor Carrasco es Premio Príncipe Felipe a la Excelencia Empresarial en Diseño y está presente en más de 80 países, donde participa en el desarrollo de mobiliario colaborativo para empresas como Apple, Google o Linkedin entre otras, ayudando así a fomentar la colaboración, la creatividad y la productividad en sus espacios de trabajo.

VISITA A KOO INTERNACIONAL

Por parte de KOO internacional el grupo fue atendido por José Muñoz, Director de Fábrica, Jorge Mompó, Director Técnico y Diana Castellano, Directora de Marketing e Innovación.

Diana realizó una interesante exposición de la empresa, y especialmente de un concepto por el que la empresa apuesta, con la colaboración de la Sección de GPS de AIDIMME, el de economía circular.

José Muñoz y Jorge Mompó intercambiaron impresiones con alumnos y profesores de SMARTRAIN acerca de las características clave de sus productos, tales como resistencia de los mismos, posibilidades de actualización y reparación de productos, tipos de material de relleno, etc…

KOO International es una empresa productora de muebles de asiento, con más de veinte años de experiencia en el sector, en la que crean piezas basadas en el diseño, la innovación y la coherencia. Cuenta con numerosos premios en diseño de productos, colaborando con afamados diseñadores.

Bajo la denominación de CIRKOOLAR, los profesores y alumnos de SMARTRAIN pudieron conocer cómo realiza la empresa esta aproximación al concepto de circularidad: https://www.koointernational.com/landings/cirkoolar/

VISITA A EMUCA

La visita en esta empresa fue conducida por Carlos Flores, Corporate Manager, y Andrea Savala del Departamento de Marketing.

En el GRUPO EMUCA diseñan, fabrican y comercializan una amplia gama de productos destinados a los sectores del mueble, la carpintería, la ferretería y el bricolaje.

La empresa cuenta con sedes comerciales de España, Italia, Reino Unido, Francia y Portugal, lo que les nos permite estar en contacto directo con las últimas tendencias del sector del mueble que su departamento de Innovación traslada posteriormente a sus productos.

Los alumnos conocieron el concepto de mueble inteligente, según la percepción de EMUCA, en el que las necesidades del usuario juegan un papel clave, sin perder de vista conceptos como sostenibilidad y economía circular.

VISITA A MOBILIARIO ROYO

La última visita se realizó a la empresa más importante de mueble de baño de Europa, ROYOGROUP, y su posición se ha reforzado desde 2021 con la alianza con el grupo ROCA, pasando a encargarse de fabricar los muebles de baño de la firma.

Se trata de una empresa comprometida con la sostenibilidad, la modernización de los procesos productivos y es muy activa en el campo de la I+D+i, participando en numerosos proyectos de investigación.

En esta ocasión la persona encargada de la visita por parte de ROYOGROUP fue Rafael Lozano, Especialista en Procesos de la empresa.

Durante la visita los alumnos y profesores pudieron conocer de primera mano el proceso productivo de esta empresa, las características de determinados materiales empleados, asi como la gran variedad de productos de mobiliario de baño fabricados. Es una gran empresa industrial, que resultó interesante para los alumnos y profesores.

Muchas gracias a todas las empresas visitadas por su atención.

El proyecto SMARTRAIN entra en su recta final y en breve se presentarán los resultados de los proyectos realizados por los tres grupos de España, Italia y Bélgica.

SMARTRAIN. BRIDGING PIVOTAL COMPETENCIES FROM VET CURRICULA TO CO-CREATION IN FURNITURE DESIGN

Número de proyecto: 22000050

Expediente: 2020-1-ES01-KA202-082778

Duración: Del 01/10/2020 al 30/09/2022

Coordinado en AIDIMME por: SORIANO CARDO,CARLOS

Línea de I+D: INDUSTRIA 4.0

Para más información, contacte con AIDIMME

Visitas: [wpstatistics stat=pagevisits time=total id=29851]

Second mobility of the european project Erasmus+ Smartrain in Italy

The SMARTRAIN project continues with its progress, and this time the second mobility was held in Italy, during the week of March 7 to 11 2021.

Students and teachers of the project, together with technical managers of the project partners, travelled to the headquarters of Enaip Lombardia in Cantu, Lombardy region, in northern Italy. There, a set of activities were carried out with the common link of 3D printing, teamwork and based on the projects that each of the groups are developing, and their usefulness for the wood-furniture sector.

During the mobility, Enaip Lombardia, coordinated by Sara Tettamanti, responsible for the International Area of this entity, organized an attractive schedule for this mobility within the project. Activities ranged from group dynamics/games to promote teamwork, to training activities on 3D, practical activities on 3D modelling on 3D printers and laser cutting equipment, including a series of visits to ENAIP’s FABLAB facilities, to two local companies: TABU and RIVA 1920, and to the Polytechnic University of Milan.

The working sessions were held in ENAIP’s FABLAB, with an initial contact with the areas available to the users of this ENAIP centre.

This space has three different areas:

- An event area to host meetings and workshops on design and wood design;

- A cultural area with 3 important furniture design collections «Neoliberty e Dintorni» and «Mobili come aforismi – 35 mobili del razionalismo italiano» belonging to Federlegno Arredo eventi spa, Collezione «Bruno Munari» belonging to the Municipality of Cantù and the Associazione Amici dei Musei di Cantù. There is also a library with over 3,000 magazines, 2,000 books and publications on wood and wood design area;

- An experimentation area where there is the ToMake FabLab, open to local schools, young students and companies.

The students participating in the mobility were distributed in mixed groups, with a mix of nationalities in each team. Together with the teachers, they worked with guidelines to start the tasks in which each working group had to name their product and to think, co-create, design and make the logo related to their product, using 3D printing and laser cutting. Beforehand, the participants played a game to break the ice amongthem, in which they were aware of the limitations of language (which are not so much), of the different points of view in different environments, with people who think differently, etc.

On the other hand, during this day, each of the working groups presented their projects, based on the initial training they had in Belgium, on key concepts of circular economy. The products presented have different characteristics.

Once the logos were defined, each working team built prototypes with the materials and equipment available at the FAB LAB, experimenting with materials, processing, options, etc.

Visits to companies and institutions

The visits included Enaip’s wood and furniture training workshops, the companies TABU, Riva1920, and the Politecnico di Milano.

Visit to Enaip’s workshop

Enaip’s workshop is equipped with modern machinery for wood and furniture students. It works mainly on interior fittings for buildings:

Students and teachers exchanged views on processes, materials and designs they work on at the Centre, etc.

Visit to TABU

TABU is an acronym of the name of the Tagliabue family, who founded it three generations ago.It is an authentic wood tailoring company that is constantly researching into the processes of dyeing technology applied to dozens of wood species. Its core business is the production of wood veneers and the dyeing process, which guarantees colour homogeneity and infinite replicability: the certainty of colour is fundamental for a customer industry.

Visit to Riva 1920

Founded in Brianza in 1920, Riva 1920 has been producing solid wood furniture of all kinds for over a hundred years. It produces everything from tables, to chairs, to bookcases, to entire kitchens: everything is made by specialized professional craftsmen, who create true works of art in wood. Riva is one of the companies that contributes most to reinforcing the perception of «Made in Italy» worldwide.

As indicated on its website, the RIVA CENTER is a striking building clad entirely in Siberian larch wood, which opened in 2010.

The cladding is the result of a design idea of Renzo Piano’s Building Workshop d carried out by Harvard University. Inside the building, you can visit a museum with lots of tools and tools for woodworking, a showroom and the PANGEA LAB with a very complete xylotheque.

It is worth noting the existence of tables made of very old wood. The centrepiece of this space is the Antico table, 12 meters of 48,000-years-old Kauri wood from New Zealand , with an iron base designed by the architect Renzo Piano.

Visit to the Milan polytechnic

The group visited one of the world’s leading universities for DESIGN studies in all its dimensions. The SMARTRAIN project group visited the laboratory of the Wood Design course, as well as other laboratories of the School of Design. The person in charge of the subject explained the activities that carried out, design strategies, concepts, etc. of great interest for the whole group. A Colombian student of the Master’s in Design, specialised in the field of service design, told the group her personal story until she came to study in this centre and gave the students valuable advice about the existing possibilities.

It has been a very interesting mobility in terms of group and collaborative work, progress in certain aspects of the projects of the three groups, and a series of very enriching visits in terms of possibilities, ideas, materials, designs, to incorporate in their projects, etc.

The consortium, especially the Spanish group, showed the draft of the mobility planning to be held in May in Spain, which is preparing agenda schedule of activities focused on the final progress of the projects, f smart furniture concepts, and a series of visits to several companies of interest for the objectives of the SMARTRAIN project.

SMARTRAIN. BRIDGING PIVOTAL COMPETENCIES FROM VET CURRICULA TO CO-CREATION IN FURNITURE DESIGN

Project Number: 22000050

Grant Agreement: 2020-1-ES01-KA202-082778

Duration: From 01/10/2020 to 30/09/2022

Coordinated at AIDIMME by: SORIANO CARDO, CARLOS

R&D Line: INDUSTRY 4.0

For more information, contact AIDIMME.

Visitors: [wpstatistics stat=pagevisits time=total id=27431]

Segunda movilidad del proyecto europeo Erasmus+ Smartrain en Italia

El proyecto SMARTRAIN continua con su andadura, y en esta ocasión se ha celebrado la segunda movilidad en Italia, durante la semana del 7 al 11 de marzo de 2021.

Los alumnos y profesores del proyecto, junto a responsables técnicos de los socios del proyecto, se desplazaron a la sede de Enaip Lombardia en Cantú, región Lombardía, en el norte de Italia, donde se realizaron un conjunto de actividades con el nexo común de la impresión 3D, trabajo en equipo y basado en los proyectos que están desarrollando cada uno de los grupos, y su utilidad para el sector de la madera-mueble.

Durante movilidad, Enaip Lombardia, con la coordinación de Sara Tettamanti, responsable del Área internacional de esta entidad, organizó una atractiva agenda para esta movilidad dentro del proyecto. Se realizaron desde actividades consistentes en dinámicas/juegos de grupo para favorecer el trabajo en equipo, hasta actividades formativas sobre 3D, actividades prácticas de modelado en impresoras 3d y equipos de corte por láser, pasando por una serie de visitas a las instalaciones de FABLAB de Enaip, a dos empresas de la zona: TABU y Riva 1920 y al Politécnico de Milán.

Las sesiones de trabajo se realizaron en el FABLAB de Enaip, con una primera toma de contacto con las áreas a disposición de los usuarios de este centro de Enaip.

Este espacio cuenta con tres áreas diferenciadas:

- Un área de eventos para acoger encuentros y talleres de diseño y diseño en madera;

- Un área cultural donde se encuentran 3 importantes colecciones de diseño de muebles «Neoliberty e Dintorni» y «Mobili come aforismi – 35 mobili del razionalismo italiano» pertenecientes a Federlegno Arredo eventi spa, Collezione «Bruno Munari» perteneciente al Ayuntamiento de Cantù y a la Associazione Amici dei Musei di Cantù. También hay una biblioteca con más de 3.000 revistas, 2.000 libros y publicaciones sobre la madera y el área de diseño de la madera;

- Una zona de experimentación donde se encuentra el ToMake FabLab abierto a las escuelas locales, a los jóvenes estudiantes y a las empresas.

Los alumnos participantes en la movilidad, se distribuyeron en grupos mixtos, con una mezcla de nacionalidades en cada equipo. Junto a los profesores, trabajaron con unas pautas para iniciar las tareas en las que cada grupo de trabajo iba a nombrar su producto y a pensar, co-crear, diseñar y realizar el logo relacionado con su producto, mediante impresión 3d y corte láser. Previamente se realizó un juego para romper el hielo entre los asistentes, en el que fueron conscientes de las limitaciones del lenguaje, (que no lo son tanto), de los diferentes puntos de vista en entornos diferentes, con personas que piensan diferente, etc…

Por otro lado, durante este día, cada uno de los grupos de trabajo presentó sus proyectos realizados a partir de la formación inicial que tuvieron en Bélgica, sobre conceptos clave de economía circular. Los productos presentados tienen características diferenciadas.

Una vez definidos los logos, cada equipo de trabajo realizó prototipos con los materiales y equipos a su disposición dentro del FAB LAB, experimentando con materiales, procesados, opciones, etc…

Visitas a empresas e instituciones

Las visitas realizadas incluyeron los talleres de formación en madera y mueble de Enaip, las empresas TABU, Riva1920, y al Politécnico de Milán.

Visita a taller de Enaip

El taller de Enaip cuenta con maquinaria moderna para los estudiantes de madera y mueble y trabaja sobre todo para equipamientos de interior de edificios:

Los alumnos y profesores intercambiaron impresiones acerca de procesos, materiales, diseños en los que trabajan en el Centro, etc…

Visita a TABU

TABU es un acrónimo del nombre de la familia Tagliabue, que la fundó hace tres generaciones, y es una auténtica sastrería de madera que investiga constantemente en los procesos de la tecnología de teñido aplicada a decenas de especies de madera. Su actividad fundamental es la elaboración de chapas de madera y el proceso teñido, que garantiza la homogeneidad del color y su infinita replicabilidad: esto es fundamental para una industria cliente, la certeza del color.

Visita a Riva 1920

Creada en Brianza en 1920, la empresa Riva 1920 produce desde hace más de cien años muebles de madera maciza de todo tipo. Desde mesas, a sillas, librerías, hasta cocinas enteras: Todo está realizado por artesanos profesionales especializados, que realizan verdaderas obras de arte en madera, y es una de las empresas que más contribuye a reforzar la percepción del “Made in Italy” en todo el mundo.

Se visitó el RIVA CENTER, una de las instalaciones más emblemáticas de la firma italiana.

Según se indica en su página web, el RIVA CENTER es un llamativo edificio totalmente revestido de madera de alerce siberiano, inaugurado en 2010.

El revestimiento es el resultado de una idea de diseño del Renzo Piano Building Workshop realizada por la Universidad de Harvard. En su interior se puede visitar un museo con infinidad de herramientas y útiles para el trabajo de madera, un showroom y el PANGEA LAB con una xiloteca muy completa.

Destaca la existencia de mesas realizadas con madera muy antigua. La estrella de este espacio es la mesa Antico, 12 metros de madera Kauri, proveniente de Nueva Zelanda, de 48.000 años de antigüedad, con una base de hierro diseñada por el arquitecto Renzo Piano.

Visita al politécnico de Milán

El grupo visitó una de las universidades más punteras y referente en el mundo para estudios de DISEÑO en todas sus dimensiones. El grupo del proyecto SMARTRAIN visitó el laboratorio de la asignatura de Diseño en Madera, además de otros laboratorios de la Escuela de Diseño. El Responsable de la asignatura explicó las actividades que se realizan, estrategias de diseño, conceptos, etc… de gran interés para todo el grupo. Una alumna colombiana del Master en Diseño, especializándose en el campo de diseño de servicios comentó al grupo su historia personal hasta llegar a estudiar en este centro y dio a los alumnos valiosos consejos acerca de las posibilidades existentes.

Ha sido una movilidad muy interesante en cuanto a trabajo en grupo y colaborativo, avances en determinados aspectos de los proyectos de los tres grupos, y una serie de visitas muy enriquecedoras en cuanto a posibilidades en cuanto a ideas, materiales, diseños, para incorporar a sus proyectos, etc…

El consorcio, especialmente el grupo español, mostró el borrador de planificación de la movilidad que se va a realizar en mayo en España, en la que se está preparando una agenda de actividades centrada en el avance final de los proyectos, conceptos de mueble inteligente, y una serie de visitas a una serie de empresas de interés, para los objetivos del proyecto SMARTRAIN.

SMARTRAIN. BRIDGING PIVOTAL COMPETENCIES FROM VET CURRICULA TO CO-CREATION IN FURNITURE DESIGN

Número de proyecto: 22000050

Expediente: 2020-1-ES01-KA202-082778

Duración: Del 01/10/2020 al 30/09/2022

Coordinado en AIDIMME por: SORIANO CARDO,CARLOS

Línea de I+D: INDUSTRIA 4.0

Para más información contacte con AIDIMME.

Visitas: [wpstatistics stat=pagevisits time=total id=27431]

Second mobility of the european project Erasmus+ Smartrain in Italy

The SMARTRAIN project continues with its progress, and this time the second mobility was held in Italy, during the week of March 7 to 11 2021.

Students and teachers of the project, together with technical managers of the project partners, travelled to the headquarters of Enaip Lombardia in Cantu, Lombardy region, in northern Italy. There, a set of activities were carried out with the common link of 3D printing, teamwork and based on the projects that each of the groups are developing, and their usefulness for the wood-furniture sector.

During the mobility, Enaip Lombardia, coordinated by Sara Tettamanti, responsible for the International Area of this entity, organized an attractive schedule for this mobility within the project. Activities ranged from group dynamics/games to promote teamwork, to training activities on 3D, practical activities on 3D modelling on 3D printers and laser cutting equipment, including a series of visits to ENAIP’s FABLAB facilities, to two local companies: TABU and RIVA 1920, and to the Polytechnic University of Milan.

The working sessions were held in ENAIP’s FABLAB, with an initial contact with the areas available to the users of this ENAIP centre.

This space has three different areas:

- An event area to host meetings and workshops on design and wood design;

- A cultural area with 3 important furniture design collections «Neoliberty e Dintorni» and «Mobili come aforismi – 35 mobili del razionalismo italiano» belonging to Federlegno Arredo eventi spa, Collezione «Bruno Munari» belonging to the Municipality of Cantù and the Associazione Amici dei Musei di Cantù. There is also a library with over 3,000 magazines, 2,000 books and publications on wood and wood design area;

- An experimentation area where there is the ToMake FabLab, open to local schools, young students and companies.

The students participating in the mobility were distributed in mixed groups, with a mix of nationalities in each team. Together with the teachers, they worked with guidelines to start the tasks in which each working group had to name their product and to think, co-create, design and make the logo related to their product, using 3D printing and laser cutting. Beforehand, the participants played a game to break the ice amongthem, in which they were aware of the limitations of language (which are not so much), of the different points of view in different environments, with people who think differently, etc.

On the other hand, during this day, each of the working groups presented their projects, based on the initial training they had in Belgium, on key concepts of circular economy. The products presented have different characteristics.

Once the logos were defined, each working team built prototypes with the materials and equipment available at the FAB LAB, experimenting with materials, processing, options, etc.

Visits to companies and institutions

The visits included Enaip’s wood and furniture training workshops, the companies TABU, Riva1920, and the Politecnico di Milano.

Visit to Enaip’s workshop

Enaip’s workshop is equipped with modern machinery for wood and furniture students. It works mainly on interior fittings for buildings:

Students and teachers exchanged views on processes, materials and designs they work on at the Centre, etc.

Visit to TABU

TABU is an acronym of the name of the Tagliabue family, who founded it three generations ago.It is an authentic wood tailoring company that is constantly researching into the processes of dyeing technology applied to dozens of wood species. Its core business is the production of wood veneers and the dyeing process, which guarantees colour homogeneity and infinite replicability: the certainty of colour is fundamental for a customer industry.

Visit to Riva 1920

Founded in Brianza in 1920, Riva 1920 has been producing solid wood furniture of all kinds for over a hundred years. It produces everything from tables, to chairs, to bookcases, to entire kitchens: everything is made by specialized professional craftsmen, who create true works of art in wood. Riva is one of the companies that contributes most to reinforcing the perception of «Made in Italy» worldwide.

As indicated on its website, the RIVA CENTER is a striking building clad entirely in Siberian larch wood, which opened in 2010.

The cladding is the result of a design idea of Renzo Piano’s Building Workshop d carried out by Harvard University. Inside the building, you can visit a museum with lots of tools and tools for woodworking, a showroom and the PANGEA LAB with a very complete xylotheque.

It is worth noting the existence of tables made of very old wood. The centrepiece of this space is the Antico table, 12 meters of 48,000-years-old Kauri wood from New Zealand , with an iron base designed by the architect Renzo Piano.

Visit to the Milan polytechnic

The group visited one of the world’s leading universities for DESIGN studies in all its dimensions. The SMARTRAIN project group visited the laboratory of the Wood Design course, as well as other laboratories of the School of Design. The person in charge of the subject explained the activities that carried out, design strategies, concepts, etc. of great interest for the whole group. A Colombian student of the Master’s in Design, specialised in the field of service design, told the group her personal story until she came to study in this centre and gave the students valuable advice about the existing possibilities.

It has been a very interesting mobility in terms of group and collaborative work, progress in certain aspects of the projects of the three groups, and a series of very enriching visits in terms of possibilities, ideas, materials, designs, to incorporate in their projects, etc.

The consortium, especially the Spanish group, showed the draft of the mobility planning to be held in May in Spain, which is preparing agenda schedule of activities focused on the final progress of the projects, f smart furniture concepts, and a series of visits to several companies of interest for the objectives of the SMARTRAIN project.

SMARTRAIN. BRIDGING PIVOTAL COMPETENCIES FROM VET CURRICULA TO CO-CREATION IN FURNITURE DESIGN

Project Number: 22000050

Grant Agreement: 2020-1-ES01-KA202-082778

Duration: From 01/10/2020 to 30/09/2022

Coordinated at AIDIMME by: SORIANO CARDO, CARLOS

R&D Line: INDUSTRY 4.0

For more information, contact AIDIMME.

Visitors: [wpstatistics stat=pagevisits time=total id=27431]