INEX-ADAM, the European Project Working to Expand Additive Manufacturing Knowledge

One of the main barriers that companies face when adopting additive manufacturing in their activity is lack of training or knowledge of materials. To address this situation, different types of training and projects are emerging with the aim of democratizing the use of 3D printing and facilitating its integration as a complementary production technology. One of these projects is the European INEX-ADAM, which arose with the goal of facilitating access to knowledge of additive manufacturing run by the University of Zagreb in the Faculty of Mechanical Engineering and Naval Architecture (UNIZAG FSB). Several institutions from different European countries have participated in it, among them, the technological center AIDIMME. We talked to Olga Jordá, R&D engineer at AIDIMME, to learn more about this interesting initiative that promotes the adoption of 3D printing in Europe.

3DN: Can you briefly introduce yourself and explain what the INEX-ADAM project is?

I am Olga Jordá, Industrial Engineer by the Polytechnic University of Valencia since 2001. I have been an R&D Engineer in the field of New Manufacturing Processes at AIDIMME since 2002, I am a specialist in additive manufacturing technologies, mainly in the development of new industrial applications, the development of training plans for knowledge transfer, and in the validation of additive manufacturing processes.

The INEX-ADAM project (INcreasing EXcellence on ADvanced Additive Manufacturing) is a European Twinning call project that started in 2018 and just ended in February 2022. The main objective is to facilitate and equip the Center for Additive Technologies, CATeh at the Faculty of Mechanical Engineering and Naval Architecture in Zagreb, Croatia, to become an industry reference center by increasing excellence and innovative capacity for research in the field of additive manufacturing.

3DN: Which European organizations are involved and what has each been responsible for?

The consortium has been formed with the objective of creating a Network of Advanced Manufacturing Expert Centers. To this end, the partners have contributed their knowledge in additive manufacturing (AM) technologies and applications to increase the competences at UNIZA

G FSB. In addition to AIDIMME, several European universities are involved in the project. Lund University in Sweden has focused on design for additive manufacturing (DfAM), selection of materials and technologies according to each type of application. The Austrian University of Mining, Metallurgy and Materials has focused on the development and processing of thermoplastic materials for FFF additive technology, as well as the characterization of materials and how to link material properties with the process. Brunel University London in England has focused its training on the state of the art of additive manufacturing, knowledge of current regulations, material modeling techniques, the innovation cooperation process and business models.

It should be noted that before starting the training period, visits were made to all partners in order to know their competences and skills, as well as the facilities of each of them, so it was easier to distribute the different topics for the training of UNIZAG FSB staff participating in the project. In addition, after the training period, all project partners participated in several workshops and summer schools specific to the design process adapted to additive manufacturing and the use of additive manufacturing in the industrial and healthcare sectors. Given the current situation, most of the workshops and conferences have been held virtually.

3DN: Specifically, what is the role of AIDIMME within this project?

AIDIMME’s participation in the INEX-ADAM project has focused on sharing its knowledge in different topics, through theoretical and practical sessions. More specifically, we have promoted knowledge on the use of metallic materials as raw material, powder bed fusion technologies, both in metal and polymer, the complete workflow of additive manufacturing, the validation of parts and the entire manufacturing process, and much more. In addition to the training, AIDIMME has participated in all the conferences, workshops and summer schools showing its knowledge in the above topics.

3DN: What is the ADAM platform and how important is it for users? What other broadcast formats do you work with?

The idea of the advanced additive manufacturing platform (ADAM platform) is to become a meeting point for intensive cooperation. The project partners will support the platform members in advanced AF applications or in the preparation of training materials. ADAM will offer opportunities for knowledge transfer, R&D, promotion, networking, industrial application and innovation for industry professionals. Experts from partner institutions are highly trained and well equipped with a wide range of AF equipment that can help to successfully solve any challenge. It is possible to apply for registration on the platform by following this link or by contacting the person in charge of platform maintenance.

In addition to the ADAM platform, the entire project consortium has participated in the elaboration of the book “A Guide to Additive Manufacturing” which is in the process of publication. In the coming months it will be available in Springer Nature in the Springer Tracts in Additive Manufacturing series and will be freely accessible to all those interested in Additive Manufacturing.

3DN: Why is it important that projects like INEX-ADAM continue to be implemented in the European framework?

Cooperation between different partners across Europe is a strength and a great enrichment for all, not only individually but also as a whole. In these difficult times, the union and collaboration between entities across Europe, the establishment of common lines of research and knowledge transfer, are the key to strengthening the European industry.

3DN: Any last words for our readers?

This type of European projects where there is collaboration and cooperation between entities throughout Europe are of great importance since knowledge and opinions are shared and the state of evolution of a given technology in the different countries is known first hand. Three years of collaboration in the project generates an atmosphere of trust and collaboration that enriches all project participants. In addition, this project focused on knowledge transfer has revealed the importance and the need for formal training in this area in general in all project partner countries that can be extended to Europe. You can find more information about the project HERE.

You can access the full publication through this link.

Project Number: 21700189

Grant Agreement: 810708

Duration: From 01/07/2018 to 28/02/2022

Coordinated in AIDIMME by: JORDA FERRANDO, OLGA

R&D Line: ADDITIVE MANUFACTURE

For more information contact AIDIMME.

Visitors: [wpstatistics stat=pagevisits time=total id=27917]

INEX-ADAM, el proyecto que amplia el conocimiento sobre la fabricación aditiva

Una de las principales barreras con las que se encuentran las empresas a la hora de adoptar la fabricación aditiva en su actividad es la falta de formación o conocimiento en esta material. Para hacer frente a esta situación, están surgiendo diferentes tipos de formaciones y proyectos con el objetivo de democratizar la utilización de la impresión 3D y facilitar su integración como tecnología de producción complementaria. Uno de estos proyectos es el europeo INEX-ADAM, que surge con la idea de facilitar el acceso al conocimiento de la fabricación aditiva por parte de la Facultad de Ingeniería Mecánica y Arquitectura Naval de Zagreb. En él han participado varias instituciones de diferentes países europeos, entre ellos, el centro tecnológico AIDIMME. Hemos hablado con Olga Jordá, ingeniera de I+D en AIDIMME, para conocer más a cerca de esta interesante iniciativa que fomenta la adopción de la impresión 3D en Europa.

3DN: ¿Puedes presentarte brevemente y explicar qué es el proyecto INEX-ADAM?

Soy Olga Jordá, Ingeniera Industrial por la Universidad Politécnica de Valencia desde el 2001. Ingeniera de I+D en el área de Nuevos procesos de fabricación de AIDIMME desde 2002, especialista en las tecnologías de fabricación aditiva, principalmente en el desarrollo de nuevas aplicaciones industriales, el desarrollo de planes de formación para transferencia de conocimiento, y en la validación de los procesos de fabricación aditiva.

El proyecto INEX-ADAM (INcreasing EXcellence on ADvanced Additive Manufacturing) es un proyecto europeo de la convocatoria Twinning que empezó en el 2018 y acaba de terminar en febrero del 2022. El objetivo principal es facilitar y dotar de conocimientos al Centro de Tecnologías Aditivas, CATeh de la Facultad de Ingeniería Mecánica y Arquitectura Naval de Zagreb, Croacia, para que se convierta en un centro de referencia sectorial mediante el aumento de la excelencia y capacidad innovadora para la investigación en el campo de la fabricación aditiva.

3DN: ¿Qué organizaciones europeas están involucradas y de qué se ha encargado cada una?

El consorcio ha sido formado con el objetivo de crear una Red de Centros Expertos en Fabricación Avanzada. Para ello, los socios han aportado su conocimiento en tecnologías y aplicaciones de la fabricación aditiva (FA) para incrementar las competencias de UNIZAG FSB. Además de AIDIMME, en el proyecto intervienen varias universidades europeas. La Universidad Lund de Suecia se ha centrado en el diseño para fabricación aditiva (DfAM), selección de los materiales y tecnologías según cada tipo de aplicación. La Universidad de Minería, Metalurgia y Materiales de Austria, se ha centrado en el desarrollo y procesado de materiales termoplásticos para la tecnología aditiva FFF, así como la caracterización de los materiales y como enlazar las propiedades del material con el proceso. La Universidad Brunel de Inglaterra ha centrado su formación en el estado del arte de la fabricación aditiva, en el conocimiento de la normativa actual, las técnicas de modelado de materiales, el proceso de cooperación en innovación y los modelos de negocio.

Cabe destacar que antes de iniciar el periodo de formación se realizaron visitas a todos los socios con el fin de conocer sus competencias y habilidades, así como las instalaciones de cada uno de ellos, de este modo fue mas sencillo la distribución de los diferentes temas para la formación del personal de UNIZAG FSB participante en el proyecto. Además, tras el periodo de formación, todos los socios del proyecto, han participado en varios talleres y escuelas de verano específicos para el proceso de diseño adaptado a fabricación aditiva y el uso de la fabricación aditiva en el sector industrial y en el sector sanitario. Dada la situación actual la mayoría de los talleres y conferencia se han realizado de forma virtual.

3DN: En concreto, ¿cuál es la función de AIDIMME dentro de este proyecto?

La participación de AIDIMME en el proyecto INEX-ADAM se ha centrado en compartir su conocimiento en diferentes temáticas, mediante sesiones teóricas y prácticas. En concreto hemos fomentado el conocimiento en cuanto al uso de materiales metálicos como materia prima, tecnologías de fusión por lecho de polvo, tanto en metal como en polímero, el workflow completo de la fabricación aditiva, la validación de piezas y de todo el proceso de fabricación, y mucho más. Además de la formación, AIDIMME ha participado en todas las conferencias, workshops y escuelas de verano mostrando su conocimiento en las temáticas anteriores.

3DN: ¿En qué campos de aplicación destaca AIDIMME en fabricación aditiva?¿Por qué es interesante para las empresas españolas?

AIDIMME es un Instituto Tecnológico de referencia que cuenta con más de 30 años de experiencia en diferentes sectores de aplicación, contribuyendo a incrementar la competitividad de las empresas en los mercados nacionales e internacionales. La Unidad de Nuevos Procesos de fabricación (NPF) de AIDIMME aplica la innovación en los procesos, principalmente, en aquellos apoyados en la aplicación de tecnologías de fabricación aditiva. Con esta Unidad se persigue que la impresión 3D se convierta en un vector de competitividad para las empresas, a través de diferentes servicios.

AIDIMME tiene una elevada experiencia en las tecnologías de Fabricación Aditiva desde el 1997 donde incorporó su primera máquina de fabricación aditiva que procesaba resina. En los últimos años el departamento de Nuevos Procesos de Fabricación ha crecido notablemente disponiendo de 13 tecnologías de fabricación aditiva que procesan un gran numero de materiales metálicos, así como poliméricos. En la actualidad, AIDMME es considerado como uno de los centros tecnológicos más relevantes en la materia con un alto compromiso de transferencia y colaboración con la industria. Cientos de empresas han confiado en nosotros para la adopción de estas novedosas tecnologías de fabricación.

3DN: ¿Qué es la plataforma ADAM y cuál es su importancia para los usuarios? ¿Con qué otros formatos de difusión trabajáis?

La idea de la plataforma de fabricación aditiva avanzada (plataforma ADAM) es convertirse en un punto de encuentro para la cooperación intensiva. Los socios del proyecto apoyarán a los miembros de la plataforma en aplicaciones de la FA avanzada o en la preparación de materiales didácticos. ADAM ofrecerá oportunidades para la transferencia de conocimiento, I+D, promoción, creación de redes, aplicación industrial e innovación para profesionales de la industria. Los expertos de las instituciones socias están altamente capacitados y bien equipados con una amplia gama de equipos de FA que pueden ayudar a resolver con éxito cualquier desafío. Es posible solicitar el registro en la plataforma en este enlace o bien contactando con la persona encargada del mantenimiento de la plataforma.

Además de la plataforma ADAM, todo el consorcio del proyecto hemos participado en la elaboración del libro “A Guide to Additive Manufacturing” que esta en proceso de publicación. En los próximos meses estará disponible en Springer Nature en la serie Springer Tracts in Additive Manufacturing y será de acceso libre para todas aquellas personas interesadas en la Fabricación Aditiva.

3DN: ¿Por qué es importante que proyectos como INEX-ADAM se sigan implementando en el marco europeo?

La cooperación entre diferentes socios a lo largo de Europa implica una fortaleza y un gran enriquecimiento para todos, no solo de forma particular sino también como conjunto. En estos tiempos tan difíciles, la unión y colaboración entre entidades a lo largo de Europa, el establecimiento de unas líneas de investigación comunes y una transferencia de conocimiento, son la clave para fortalecer la industria Europea.

3DN: ¿Unas últimas palabras para nuestros lectores?

Este tipo de proyectos europeos donde hay una colaboración y cooperación entre entidades a lo largo de Europa son de gran importancia ya que se comparte conocimiento, opiniones y se conoce de primera mano el estado de la evolución de una determinada tecnología en los diferentes países. Tres años de colaboración en el proyecto hace que se genere un ambiente de confianza y colaboración que enriquece a todos los participantes del proyecto. Además, este proyecto centrado en la transferencia de conocimiento ha revelado la importancia y la necesidad de formación reglada en esta temática en general en todos los países socios del proyecto que puede hacerse extensivo a Europa. Puedes encontrar más información del proyecto aquí.

Puede acceder a la publicación completa a través de este enlace.

Número de proyecto: 21700189

Expediente: 810708

Duración: Del 01/07/2018 al 28/02/2022

Coordinado en AIDIMME por: JORDA FERRANDO,OLGA

Línea de I+D: FABRICACIÓN ADITIVA

Para más información contacte con AIDIMME.

Visitas: [wpstatistics stat=pagevisits time=total id=27901]

INEX-ADAM, the European Project Working to Expand Additive Manufacturing Knowledge

One of the main barriers that companies face when adopting additive manufacturing in their activity is lack of training or knowledge of materials. To address this situation, different types of training and projects are emerging with the aim of democratizing the use of 3D printing and facilitating its integration as a complementary production technology. One of these projects is the European INEX-ADAM, which arose with the goal of facilitating access to knowledge of additive manufacturing run by the University of Zagreb in the Faculty of Mechanical Engineering and Naval Architecture (UNIZAG FSB). Several institutions from different European countries have participated in it, among them, the technological center AIDIMME. We talked to Olga Jordá, R&D engineer at AIDIMME, to learn more about this interesting initiative that promotes the adoption of 3D printing in Europe.

3DN: Can you briefly introduce yourself and explain what the INEX-ADAM project is?

I am Olga Jordá, Industrial Engineer by the Polytechnic University of Valencia since 2001. I have been an R&D Engineer in the field of New Manufacturing Processes at AIDIMME since 2002, I am a specialist in additive manufacturing technologies, mainly in the development of new industrial applications, the development of training plans for knowledge transfer, and in the validation of additive manufacturing processes.

The INEX-ADAM project (INcreasing EXcellence on ADvanced Additive Manufacturing) is a European Twinning call project that started in 2018 and just ended in February 2022. The main objective is to facilitate and equip the Center for Additive Technologies, CATeh at the Faculty of Mechanical Engineering and Naval Architecture in Zagreb, Croatia, to become an industry reference center by increasing excellence and innovative capacity for research in the field of additive manufacturing.

3DN: Which European organizations are involved and what has each been responsible for?

The consortium has been formed with the objective of creating a Network of Advanced Manufacturing Expert Centers. To this end, the partners have contributed their knowledge in additive manufacturing (AM) technologies and applications to increase the competences at UNIZA

G FSB. In addition to AIDIMME, several European universities are involved in the project. Lund University in Sweden has focused on design for additive manufacturing (DfAM), selection of materials and technologies according to each type of application. The Austrian University of Mining, Metallurgy and Materials has focused on the development and processing of thermoplastic materials for FFF additive technology, as well as the characterization of materials and how to link material properties with the process. Brunel University London in England has focused its training on the state of the art of additive manufacturing, knowledge of current regulations, material modeling techniques, the innovation cooperation process and business models.

It should be noted that before starting the training period, visits were made to all partners in order to know their competences and skills, as well as the facilities of each of them, so it was easier to distribute the different topics for the training of UNIZAG FSB staff participating in the project. In addition, after the training period, all project partners participated in several workshops and summer schools specific to the design process adapted to additive manufacturing and the use of additive manufacturing in the industrial and healthcare sectors. Given the current situation, most of the workshops and conferences have been held virtually.

3DN: Specifically, what is the role of AIDIMME within this project?

AIDIMME’s participation in the INEX-ADAM project has focused on sharing its knowledge in different topics, through theoretical and practical sessions. More specifically, we have promoted knowledge on the use of metallic materials as raw material, powder bed fusion technologies, both in metal and polymer, the complete workflow of additive manufacturing, the validation of parts and the entire manufacturing process, and much more. In addition to the training, AIDIMME has participated in all the conferences, workshops and summer schools showing its knowledge in the above topics.

3DN: What is the ADAM platform and how important is it for users? What other broadcast formats do you work with?

The idea of the advanced additive manufacturing platform (ADAM platform) is to become a meeting point for intensive cooperation. The project partners will support the platform members in advanced AF applications or in the preparation of training materials. ADAM will offer opportunities for knowledge transfer, R&D, promotion, networking, industrial application and innovation for industry professionals. Experts from partner institutions are highly trained and well equipped with a wide range of AF equipment that can help to successfully solve any challenge. It is possible to apply for registration on the platform by following this link or by contacting the person in charge of platform maintenance.

In addition to the ADAM platform, the entire project consortium has participated in the elaboration of the book “A Guide to Additive Manufacturing” which is in the process of publication. In the coming months it will be available in Springer Nature in the Springer Tracts in Additive Manufacturing series and will be freely accessible to all those interested in Additive Manufacturing.

3DN: Why is it important that projects like INEX-ADAM continue to be implemented in the European framework?

Cooperation between different partners across Europe is a strength and a great enrichment for all, not only individually but also as a whole. In these difficult times, the union and collaboration between entities across Europe, the establishment of common lines of research and knowledge transfer, are the key to strengthening the European industry.

3DN: Any last words for our readers?

This type of European projects where there is collaboration and cooperation between entities throughout Europe are of great importance since knowledge and opinions are shared and the state of evolution of a given technology in the different countries is known first hand. Three years of collaboration in the project generates an atmosphere of trust and collaboration that enriches all project participants. In addition, this project focused on knowledge transfer has revealed the importance and the need for formal training in this area in general in all project partner countries that can be extended to Europe. You can find more information about the project HERE.

You can access the full publication through this link.

Project Number: 21700189

Grant Agreement: 810708

Duration: From 01/07/2018 to 28/02/2022

Coordinated in AIDIMME by: JORDA FERRANDO, OLGA

R&D Line: ADDITIVE MANUFACTURE

For more information contact AIDIMME.

Visitors: [wpstatistics stat=pagevisits time=total id=27901]

INEX-ADAM European Project Final Conference

INEX-ADAM PROJECT. Increasing Excellence on Advanced Additive Manufacturing.

In this Project, AIDIMME participates as an expert partner in order to facilitate and provide knowledge to the Centre for Additive Technologies (CATeh) of the Faculty of Mechanical Engineering and Naval Architecture of Zagreb, Croatia, UNIZAG FSB (https://www.fsb.unizg.hr/) so that it becomes a centre of reference in this sector.

The INEX-ADAM European project – Increasing EXcelence on Advanced Additive Manufacturing (H2020-WIDESPREAD-05-2017-Twinning call) has come to an end after a 42-month collaboration. The final conference was based on the impact of Additive Manufacturing and future trends in AM development and new applications.

Every partner of this project delivered a presentation. The day ended with a small virtual roundtable discussion where all the attendees agreed on the necessity of education in this field in order to extend its application in the industry.

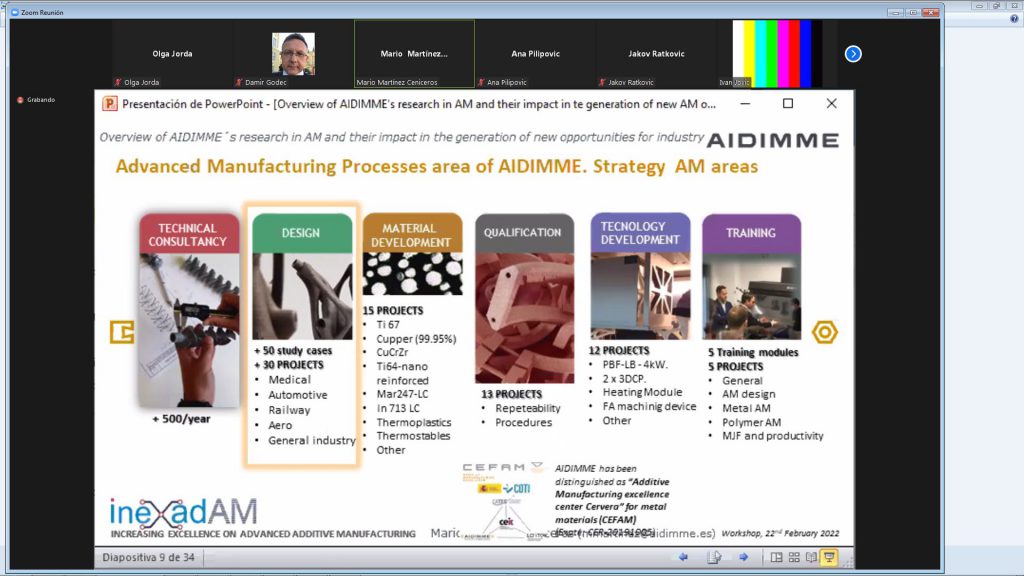

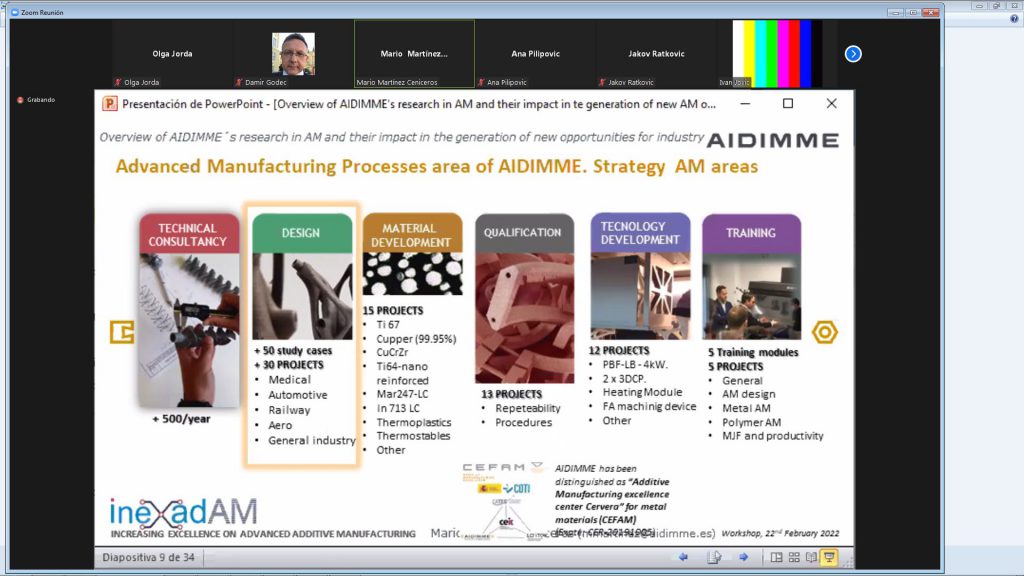

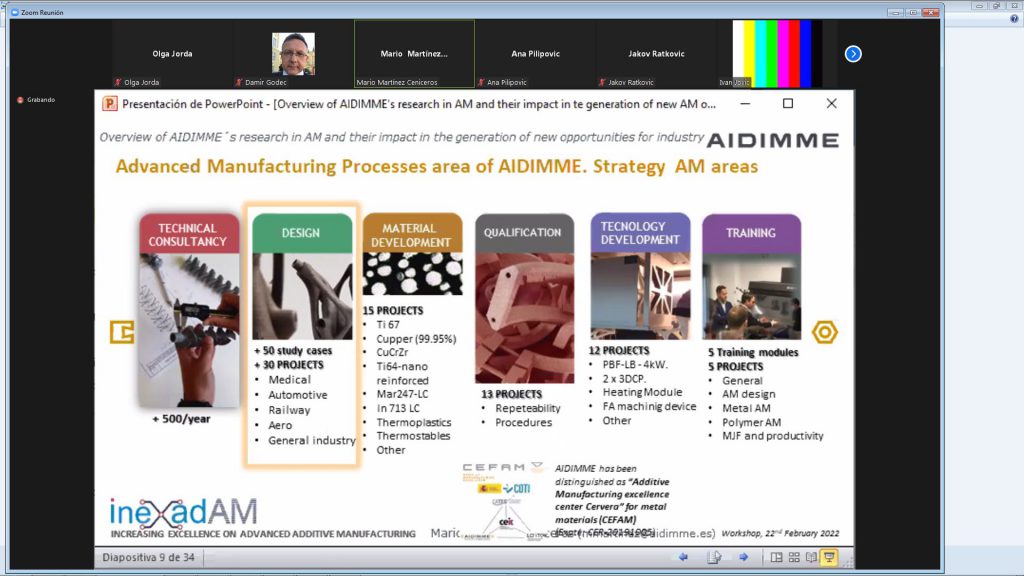

It is worth highlighting the presentation given by Mario Martínez, researcher of New Manufacturing Processes Unit of AIDIMME, who presented the “Overview of AIDIMME’s research in AM and their impact in the generation of new opportunities for the industry”. He pointed out the strategic lines of AIDIMME in Additive Manufacturing and emphasised the future activities to be carried out by each of them in order to approach these technologies to the industrial market.

All the information related to the INEX-ADAM project and the conferences can be found in the following link.

Olga Jordá

TECNOLOGÍAS Y PROCESOS

Nuevos procesos de información

INEX-ADAM – INCREASING EXCELLENCE ON ADVANCED ADDITIVE MANUFACTURING

Project Number: 21700189

Grant Agreement: 810708

Duration: From 01/07/2018 to 28/02/2022

Coordinated in AIDIMME by: JORDA FERRANDO, OLGA

R&D Line: ADDITIVE MANUFACTURE

This R&D project, file number 810708, has been funded by the European Union Programme (Horizon 2020-WIDESPREAD-05-2017-Twinning call).

For more information contact AIDIMME.

Visitors: [wpstatistics stat=pagevisits time=total id=27741]

Jornada de finalización del Proyecto Europeo INEX-ADAM

PROYECTO INEX-ADAM. Increasing Excellence on Advanced Additive Manufacturing.

En este proyecto, AIDIMME participa como socio experto con el objetivo principal de facilitar y dotar de conocimientos al Centro de Tecnologías Aditivas, CATeh de la Facultad de Ingeniería Mecánica y Arquitectura Naval de Zagreb, Croacia, UNIZAG FSB (https://www.fsb.unizg.hr/) para que se convierta en un centro de referencia sectorial.

El Proyecto Europeo INEX-ADAM – INcreasing EXcellence on ADvanced Additive Manufacturing (convocatoria H2020-WIDESPREAD-05-2017-Twinning) ha llegado a su fin tras 42 meses de colaboración, y lo hace a través de una jornada final basada en el impacto de la Fabricación Aditiva y futuras tendencias en nuevos desarrollos y nuevas aplicaciones.

Todos los socios del proyecto realizaron una presentación configurando una jornada que acabó con una pequeña mesa redonda virtual donde todos los asistentes coincidieron en la necesidad de formación en estas tecnologías para ampliar su uso en la industria.

Cabe destacar la presentación llevada a cabo por Mario Martínez, investigador de la Unidad de nuevos procesos de Fabricación de AIDIMME que presentó la ponencia “Overview of AIDIMME´s research in AM and their impact in the generation of new opportunities for industry”, resaltando las líneas estratégicas de AIDIMME en fabricación aditiva y haciendo hincapié en las futuras actividades a realizar por cada una de ellas para acercar lo máximo posible estas tecnologías al mercado industrial.

Puede consultar toda la información relativas al proyecto INEX-ADAM y a las jornadas en el siguiente enlace.

Este proyecto de I+D, con expediente 810708, ha sido financiado por el Programa de la Unión Europea (convocatoria Horizon 2020-WIDESPREAD-05-2017-Twinning).

Olga Jordá

TECNOLOGÍAS Y PROCESOS

Nuevos procesos de información

INEX-ADAM: INCREMENTANDO LA EXCELENCIA EN FABRICACIÓN ADITIVA AVANZADA

Número de proyecto: 21700189

Expediente: 810708

Duración: Del 01/07/2018 al 28/02/2022

Coordinado en AIDIMME por: JORDA FERRANDO, OLGA

Línea de I + D: FABRICACIÓN ADITIVA

El presente proyecto de I+D, con expediente 810708, está financiado por el Programa de la Unión Europea (convocatoria Horizon 2020-WIDESPREAD-05-2017-Twinning).

Para más información contacte con AIDIMME.

Visitas: [wpstatistics stat=pagevisits time=total id=27073]

INEX-ADAM European Project Final Conference

INEX-ADAM PROJECT. Increasing Excellence on Advanced Additive Manufacturing.

In this Project, AIDIMME participates as an expert partner in order to facilitate and provide knowledge to the Centre for Additive Technologies (CATeh) of the Faculty of Mechanical Engineering and Naval Architecture of Zagreb, Croatia, UNIZAG FSB (https://www.fsb.unizg.hr/) so that it becomes a centre of reference in this sector.

The INEX-ADAM European project – Increasing EXcelence on Advanced Additive Manufacturing (H2020-WIDESPREAD-05-2017-Twinning call) has come to an end after a 42-month collaboration. The final conference was based on the impact of Additive Manufacturing and future trends in AM development and new applications.

Every partner of this project delivered a presentation. The day ended with a small virtual roundtable discussion where all the attendees agreed on the necessity of education in this field in order to extend its application in the industry.

It is worth highlighting the presentation given by Mario Martínez, researcher of New Manufacturing Processes Unit of AIDIMME, who presented the “Overview of AIDIMME’s research in AM and their impact in the generation of new opportunities for the industry”. He pointed out the strategic lines of AIDIMME in Additive Manufacturing and emphasised the future activities to be carried out by each of them in order to approach these technologies to the industrial market.

All the information related to the INEX-ADAM project and the conferences can be found in the following link.

Olga Jordá

TECNOLOGÍAS Y PROCESOS

Nuevos procesos de información

INEX-ADAM – INCREASING EXCELLENCE ON ADVANCED ADDITIVE MANUFACTURING

Project Number: 21700189

Grant Agreement: 810708

Duration: From 01/07/2018 to 28/02/2022

Coordinated in AIDIMME by: JORDA FERRANDO, OLGA

R&D Line: ADDITIVE MANUFACTURE

This R&D project, file number 810708, has been funded by the European Union Programme (Horizon 2020-WIDESPREAD-05-2017-Twinning call).

For more information contact AIDIMME.

Visitors: [wpstatistics stat=pagevisits time=total id=27073]